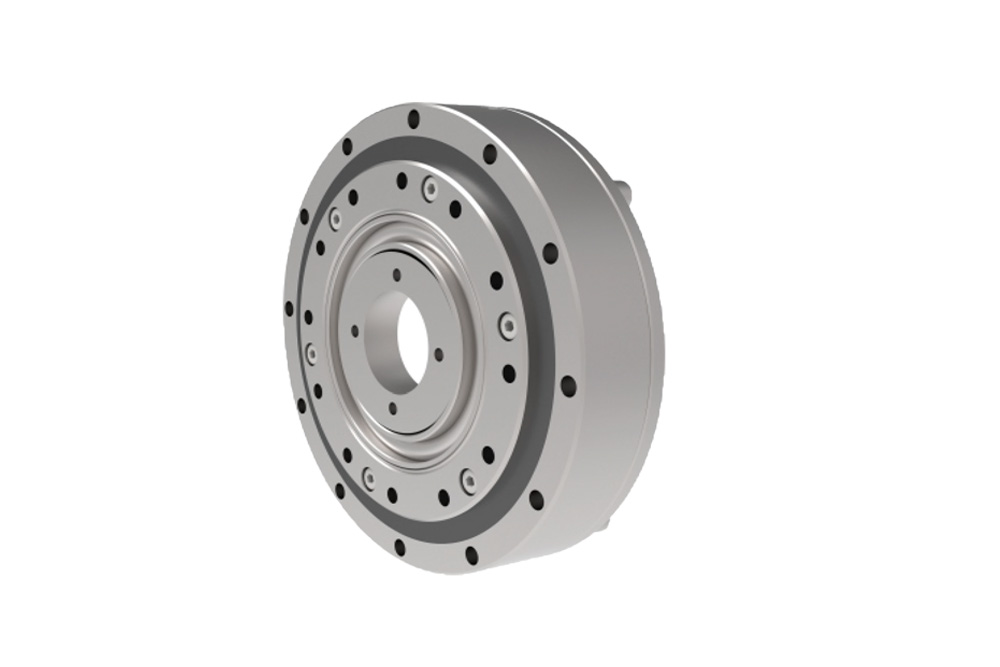

Harmonic Eeducer Transmission Composition

Deceleration principle

As a reducer, harmonious waves are generally driven by wave generator with fixed rigid spline and output by flexible spline. When wave generator is installed inside the inner ring of flexible spline, flexible spline is forced to go through elastic transformation and becomes an elliptical shape; the flexible spline teeth of long shaft insert into the gear groove of rigid spline to realize complete engagement; the gear teeth of the two splines of the short shaft are not contacted at all but disengaged. Between engagement to disengagement, gear teeth are in engaging-out or engaging-in status. When the wave generator rotates continuously, the flexible spline is forced to deform constantly, and the gear teeth of the two gears change their working status repeatedly in the engag-ing-in, engagement, engaging-out and disengagement, generating the so-called staggered teeth motion and realizing the motion transmission between active wave generator and flexible spline.

Named Rules

Harmonic Transmission Characteristics

1.Simple structure, compact design and light weightCompact design and Low WeightCCompact design and Low Weightompact design and Low Weight

In the case where the transmission ratio and the bearing conditions are comparable, the harmonic gear transmission can reduce the volume and weight of the general gear reducer by about 1/3 to 1/2.

2.High Transmission Ratio

Single-stage harmonic gearrons can reach 50-160 (if the planetary wave generator is used, the transmission ratio can be expanded to 150-4000). The drive ratio of the duplex drive can be higher.

3.The number of gear teeth participating in meshing at the same time is large

Dual-wave harmonic reducer simultaneously meshed by 30%, even more. In the normal gear transmission, only 2-7% of the number of gear meshing simultaneously, and only 1-2 pairs of teeth meshing simultaneously for the straight gear cylindrical process. It is precisely due to the simultaneous strength of the number of gear, the accuracy of the harmonic transmission is high, and the carrying capacity of the gear is large, and the large speed ratio is achieved.

4.High transmission accuracy

In the same manufacturing precision, the transmission accuracy of the harmonic gear is at least one higher than the transmission accuracy of the general gear.

5.Stable transmission, shock-Free, low-noiseStable Transmission, Shock-Free, Low-Noise

When the gear are engaged, the mesh is the deformation of the fumet, gradually enter and gradually exit the migration of the gear, and the gear surface during the meshing process, the slip speed is small, and there is no sudden change.

6.Gear gap can be adjusted

The gap between the harmonic gear drive is in engagement, the gap between the fumet and the rigid rotation depends primarily on the shape of the wave hair, and the gear shape of the two gears can be adjusted to make the transmission to the transmission. Some cases The zero gap can be reached.

7.High transmission efficiency

Harmonic transmission is small due to the number of moving components, and the speed of the moving part is low, and the efficiency is high, the efficiency is about 65, the efficiency is about 65 efficiency, and the efficiency is high, and the speed ratio is high (u = 60-250). -90% or so (low harmonic resolver transmission efficiency), the wear of the gear surface is small.

8.Input-output coaxial

The high-speed shaft and low-speed shaft of the harmonic gear reducer are located on the same axis.

9.Easy to achieve differential transmission

Due to the three basic components of the harmonic gear drive, it can be arbitrarily active, the third driven, then if the wave generator, the rigid wheel actively, the flexo wheel can constitute a differential transmission mechanism, thereby Conveniently realizing quick slow operating conditions. This is a practical value for many machine tools, which can greatly change the structural performance of the machine tool.

Industry Application

Mainly used in all kinds of light industrial robots, mechanical arms, printing, papermaking machinery, medical machinery, measurement, analysis, testing machine, large telescope, precision packaging machinery, semiconductor manufacturing device, FPD manufacturing device, communication device, aerospace machine, CNC Machine tools, radar varieties of satellite terrestrial stations, etc. have required precision drive systems.